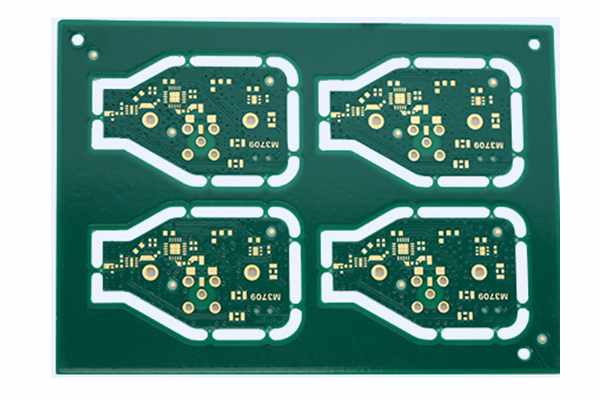

1. Ukusika

Hlola ukucaciswa, imodeli kanye nosayizi wokusika webhodi le-substrate ngokuya ngokucubungula komkhiqizo noma imidwebo ecacisiwe yokusika.Isiqondiso se-longitude ne-latitude, ubude nobubanzi bobukhulu kanye ne-perpendicularity yebhodi ye-substrate kungaphakathi kobubanzi obushiwo emdwebeni.

2. Ukuphrinta kwenqubo yesikrini sikasilika

Okokuqala, hlola ukuthi isikrini sesikrini, ukushuba kwesikrini nokuqina kwefilimu kuyahlangabezana yini nezidingo ezishiwo.

Khona-ke, hlola ubuqotho besibalo, futhi ayikho i-pinhole, i-notch noma ifilimu yokunamathela esele.Hlola ebhodini lokuqala elinezithombe, futhi usayizi wokuma kwesibalo uyavumelana, futhi ububanzi bomugqa, isikhala somugqa, usayizi wediski oxhumayo noma izimpawu zezinhlamvu ziyahambisana.

3. Ukuhlanza ubuso

Ihlanzwa ngamakhemikhaliPCBindawo engaphezulu ngeke ibe ne-oxidation kanye nokungcola, futhi iyokoma ngemva kokuhlanza.

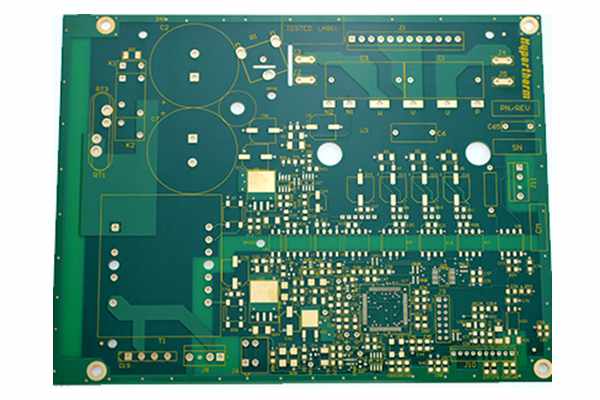

4. Ukunyathelisa kwesifunda

Hlola ubuqotho bomdwebo wesifunda, futhi ayikho isekethe evulekile, iphinikhodi, inothi noma isifunda esifushane.Hlola ngebhodi langempela lezithombe, usayizi wokuma kwesibalo uyavumelana, ububanzi bomugqa nebanga lomugqa kuyahambisana, futhi iphutha lingaphakathi kwebanga elivumelekile.

5. Ukuqopha

Hlola ubuqotho bomdwebo wesifunda, futhi ayikho isekethe evulekile, iphinikhodi, inothi noma isifunda esifushane.Hlola ebhodini lokuqala elinezithombe, futhi akukho okunamathiselwe (umugqa mncane kakhulu) noma ukushumeka akwanele (umugqa ushubile kakhulu).

6. Ukumelana nokushisela

Okokuqala, hlola ubuqotho bezithombe ze-solder resist, futhi awekho amaphrinti alahlekile, amaphinifa, ama-notches, i-seepage kayinki, izindonga ezilengayo, namabala kayinki amaningi.Ihambisana nosayizi wokuma wesibalo somugqa, futhi iphutha lingaphakathi kwebanga elivumelekile.

Okwesibili, hlola izinga lokuphulukisa le-solder resist.Isendlalelo sokumelana ne-solder ebusweni bomqhubi wethusi kufanele sihlolwe ngepensela, futhi ubulukhuni bepensela buzoba ngaphezu kuka-3H.

Okwesithathu, hlola amandla okubopha we-solder resist.Namathisela bese udonsa ungqimba lokumelana ne-solder endaweni yomhlahlandlela wethusi nge-adhesive tape.Akufanele kube khona ukumelana ne-solder ecwecwayo ku-tape.

7. Izimpawu zezinhlamvu ezinhle nezingezinhle

Hlola ubuqotho bengcaca bezimpawu zezinhlamvu, futhi akukho ukuphrinta, izimbobo, izinkinobho noma i-inki, izindonga ezilengayo, namachashazi ayinki engeziwe.Ihambisana nosayizi wokuma wezithombe zomugqa, iphutha lingaphakathi kwebanga elivumelekile, futhi uphawu lohlamvu lungabonwa ngendlela efanele.

Siyazethemba ekukunikezeni inhlanganisela engcono kakhuluisevisi yokuhlanganisa ukhiye we-PCB, ikhwalithi, intengo kanye nesikhathi sokulethwa ku-oda lakho leqoqo le-PCB leqoqwana elincane le-Mid batch Volume PCB oda lomhlangano.

Uma ufuna umkhiqizi womhlangano we-PCB okahle, sicela uthumele amafayela akho e-BOM namafayela e-PCB kusales@pcbfuture.com.Wonke amafayela akho ayimfihlo kakhulu.Sizokuthumelela isilinganiso esinembile nesikhathi sokuhola emahoreni angama-48.

Isikhathi sokuthumela: Dec-01-2022