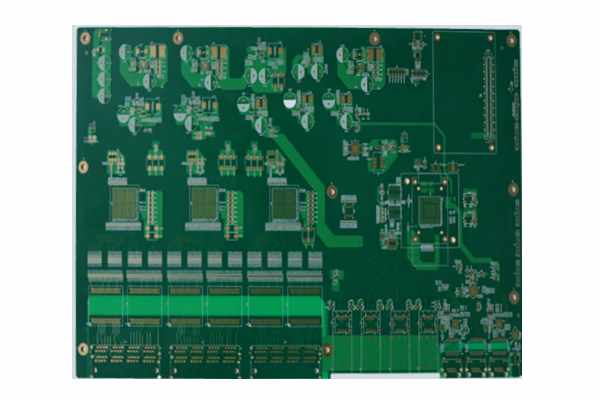

Ngokuthuthukiswa kwe-miniaturization kanye nokunemba kwemikhiqizo ye-elekthronikhi, iUkwakhiwa komhlangano we-PCBfuthi ukuminyana komhlangano osetshenziswa izitshalo ezicutshungulwa ngogesi kuya ngokuya kukhula, amalunga e-solder kumabhodi esekethe aya ngokuya eba mancane futhi abe mancane, futhi imithwalo yemishini, kagesi kanye ne-thermodynamic abayithwalayo iya ngokuya ikhuphuka.Isiya ngokuba nzima futhi nezidingo zozinzo ziyanda.Nokho, inkinga PCB umhlangano solder ukwehluleka okuhlangene kuzophinde ihlangabezane inqubo langempela processing.Kuyadingeka ukuhlaziya nokuthola imbangela yokugwema ukwehluleka kokuhlangana kwe-solder ukuthi kungenzeki futhi.

Ngakho-ke namuhla, sizokwethula kuwe izizathu eziyinhloko zokwehluleka komhlangano we-PCB wokucubungula amajoyinti e-solder.

Izizathu eziyinhloko zokwehluleka komhlangano we-PCB wokucubungula amalunga e-solder:

1. Izikhonkwane zengxenye engalungile: i-plating, ukungcola, i-oxidation, i-coplanarity.

2. Amaphedi e-PCB ampofu: i-plating, ukungcola, i-oxidation, i-warpage.

3.Iziphambeko zekhwalithi ye-Solder: ukwakheka, ukungcola okusezingeni eliphansi, i-oxidation.

4. Iziphambeko zekhwalithi ye-Flux: i-flux ephansi, ukugqwala okuphezulu, i-SIR ephansi.

5. Amaphutha okulawula ipharamitha yenqubo: ukuklama, ukulawula, imishini.

6. Okunye ukukhubazeka kwezinto ezisizayo: ama-adhesives, i-ejenti yokuhlanza.

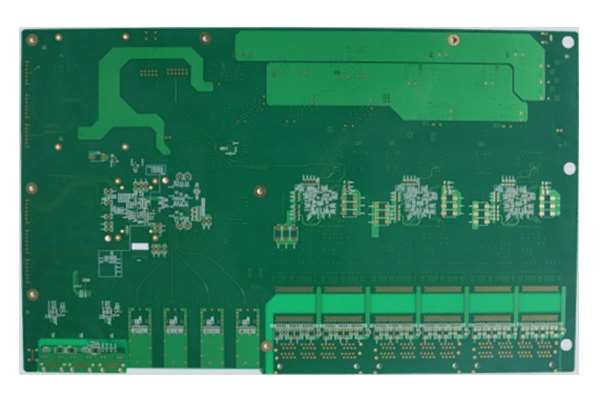

Izindlela zokwandisa ukuzinza kwamajoyinti e-solder e-PCB:

Ukuhlolwa kokuzinza kwamajoyinti e-solder e-PCB kufaka phakathi ukuhlolwa kokuzinza nokuhlaziya.

Ngakolunye uhlangothi, inhloso yayo ukuhlola nokuhlonza izinga lokuzinza lamadivayisi wesekethe ahlanganisiwe we-PCB, nokuhlinzeka ngemingcele yokuklama ukuzinza kwawo wonke umshini.

Ngakolunye uhlangothi, ohlelweni lweUkuhlanganiswa kwe-PCBukucubungula, kuyadingeka ukuthuthukisa ukuzinza kwamalungu e-solder.Lokhu kudinga ukuhlaziywa komkhiqizo ohlulekile, ukuthola imodi yokwehluleka, nokuhlaziya imbangela yokwehluleka.Inhloso iwukubuyekeza nokwenza ngcono inqubo yokuklama, imingcele yesakhiwo, inqubo yokushisela, nokuthuthukisa isivuno sokucutshungulwa komhlangano we-PCB.Imodi ukwehluleka PCB umhlangano solder amalunga yisisekelo sokubikezela ukuphila kwayo umjikelezo nokusungula imodeli yayo zezibalo.

Ngamafuphi, Kufanele sithuthukise ukuzinza kwamalungu e-solder futhi sithuthukise isivuno semikhiqizo.

I-PCBFuture izibophezele ukuhlinzeka ngekhwalithi ephezulu nangokwezomnothoIsevisi yokuhlanganisa ye-One-Stop PCBkuwo wonke amakhasimende omhlaba.Ukuze uthole ulwazi olwengeziwe, sicela usithumele i-imeyili kuservice@pcbfuture.com.

Isikhathi sokuthumela: Oct-26-2022