Inqubo yokuhlanza amanzi yomhlangano we-PCB isebenzisa amanzi njengendawo yokuhlanza.Inani elincane (ngokuvamile u-2% - 10%) lama-surfactants, ama-corrosion inhibitors namanye amakhemikhali angengezwa emanzini.Ukuhlanzwa komhlangano we-PCB kuqedwa ngokuhlanza ngemithombo yamanzi ehlukahlukene futhi yomiswe ngamanzi ahlanzekile noma amanzi angcolile.

Ngakho namuhla, sizokwethula kumgomo weUkuhlanganiswa kwe-PCBubuchwepheshe bokuhlanza amanzi kanye nezinzuzo kanye nokubi.

Izinzuzoyokuhlanza amanzi ukuthi ayinabo ubuthi, ayilimazi impilo yabasebenzi, ayishi, ayinaziqhumane, futhi inokuphepha okuhle.

Ukuhlanza amanzi kunomphumela omuhle wokuhlanza ezinhlayiyeni, i-rosin flux, ukungcola okuncibilika emanzini kanye nokungcola kwe-polar.

Ukuhlanza amanzi kunokuhambisana okuhle nezinto zokupakisha zengxenye nezinto ze-PCB.Ngeke ikhukhumale noma iqhekeze izingxenye zenjoloba kanye nezingubo, igcine izimpawu nezimpawu ebusweni bezingxenye zicacile futhi ziqinile futhi ngeke zigezwe.

Ngakho-ke, ukuhlanza amanzi kungenye yezinqubo eziyinhloko zokuhlanza okungezona i-ODS.

Ububiyokuhlanza amanzi ukuthi ukutshalwa kwezimali kwazo zonke izinto zokusebenza kukhulu, futhi kuyadingeka futhi ukutshala impahla yokukhiqiza amanzi amanzi ahlanzekile noma amanzi akhishwe.Ngaphezu kwalokho, ayifaneleki kumadivayisi angenawo umoya, njengama-potentiometers alungisekayo, ama-inductors, amaswishi, njll. Umhwamuko wamanzi ongena kudivayisi akulula ukuwukhipha, futhi ulimaza ngisho nesici sendandatho.

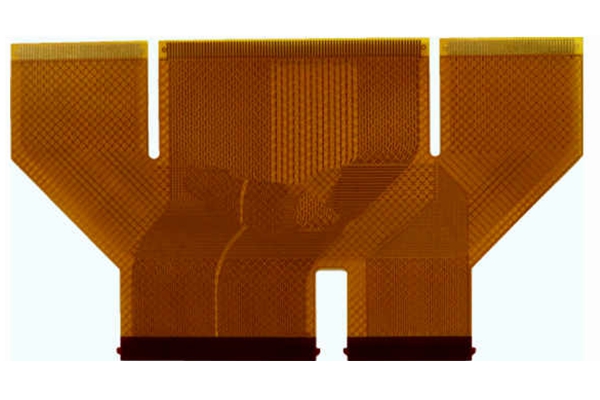

Ubuchwepheshe bokugeza bungahlukaniswa ngokuwashwa kwamanzi ahlanzekile namanzi kanye nokugeza okufakwe emanzini.

Ukugeleza kwenqubo yokuhlanganiswa kwe-PCB okujwayelekile kungokulandelayo: amanzi + i-surfactant → amanzi → amanzi ahlanzekile → amanzi acwebile → ukugeza komoya oshisayo → ukuhlanza → ukomisa.

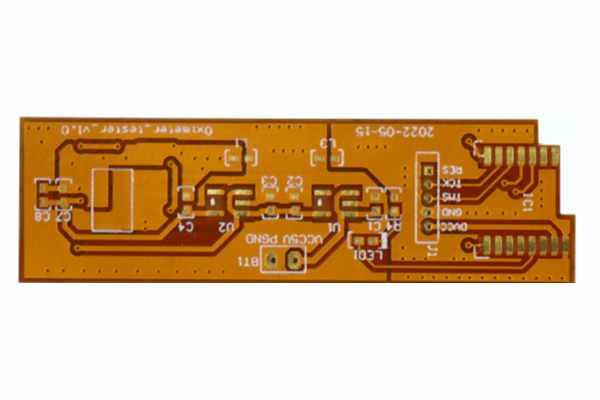

Ngaphansi kwezimo ezijwayelekile, idivayisi ye-ultrasonic yengezwe esigabeni sokuhlanza, futhi idivayisi yommese womoya (nozzle) yengezwe ngaphezu kwedivayisi ye-ultrasonic esigabeni sokuhlanza.Ukushisa kwamanzi kufanele kulawulwe ku-60-70 ° C, futhi izinga lamanzi kufanele libe phezulu kakhulu.Lobu buchwepheshe obuhlukile bufanele amabhizinisi anezidingo eziphezulu zokukhiqiza ngobuningi nokuthembeka komkhiqizo kuIzitshalo zokucubungula ama-chip e-SMT.Ukuhlanza i-batch encane, imishini yokuhlanza encane ingakhethwa.

I-PCBFuture ingumphakeli we-PCB kanye nemikhiqizo namasevisi ahlotshaniswa nawo embonini yokuklama kagesi kanye neyokwenziwa.Namuhla, bonke abakhiqizi be-elekthronikhi bayaqaphela ukuthi kungakhathaliseki ukuthi yini futhi amakhasimende abo akuphi, baqhudelana endaweni yemakethe yomhlaba wonke.Ukuze ukwazi ukuncintisana, bonke abakhiqizi badinga ukuthola abahlinzeki abaqhudelana nabo.Uma unemibuzo noma unemibuzo, zizwe ukhululekile ukuxhumanasales@pcbfuture.com.sizokuphendula ngokushesha.

Isikhathi sokuthumela: Nov-09-2022