16 uhlobokwePCB evamilei-solderingamaphutha

Enqubweni yomhlangano we-PCB, amaphutha ahlukahlukene avame ukuvela, njengokusoda okungamanga, ukushisa ngokweqile, ukubhulabhula nokunye.Ngezansi PCBfuture izochaza evamileUkuhlanganiswa kwe-PCBamaphutha lapho uthengisa ama-PCB nokuthi ungakugwema kanjani.

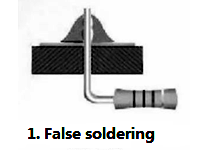

1. I-solder yamanga

Izici zokubukeka: kunomngcele omnyama osobala phakathi kwe-solder nengxenye yomthofu, noma i-copper foil, futhi i-solder i-concave emngceleni.

Ukulimala: ukungasebenzi kahle.

Isizathu: ukuhola kwezingxenye akuhlanzwa, ithini ayipuletiwe noma ithini i-oxidized.Ibhodi lesifunda eliphrintiwe alihlanzwa, futhi ikhwalithi yokufafaza i-flux ayilungile.

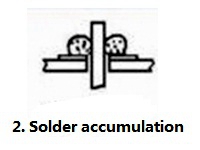

2. Ukuqoqwa kwe-solder

Izici zokubukeka: isakhiwo esihlangene se-solder sikhululekile, simhlophe futhi singenasici.

Ukulimala: amandla anganele emishini angabangela ukushisela okungamanga.

Isizathu: izinga eliphansi le-solder.Izinga lokushisa lokushisela alanele.Uma i-solder ingaqinisiwe, i-lead yengxenye ikhululekile.

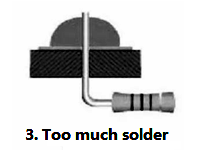

3. I-solder eningi kakhulu

Izici zokubukeka: indawo ye-solder i-convex.

Ukulimala: I-solder imoshekile futhi ukukhubazeka kungase kungabonakali kalula.

Isizathu: ukusebenza okungalungile ngesikhathi se-solder.

4. I-solder encane kakhulu

Izici zokubukeka: indawo ye-welding ingaphansi kuka-80% we-pad, futhi i-solder ayenzi indawo yokuguquka ebushelelezi.

Ukulimala: amandla emishini anganele.

Isizathu: ukunyakaza kwe-solder kuyinto embi noma ukuhoxiswa kwe-solder ngaphambi kwesikhathi.Ukuguquguquka okunganele.Isikhathi sokushisela sifushane kakhulu.

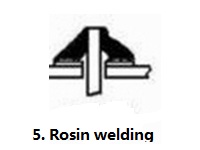

5. Ukushisela i-rosin

Izici zokubukeka: kukhona i-rosin slag ku-weld.

Ukulimala: amandla anganele, ukungahambi kahle, kwesinye isikhathi ukukhanyisa noma ukuvala.

Isizathu: kunemishini yokushisela eminingi kakhulu noma ukwehluleka kokushisela.Isikhathi sokushisela esinganele kanye nokufudumeza.Ifilimu ye-oxide engaphezulu ayizange isuswe.

6. Ukushisa ngokweqile

Izici zokubukeka: i-solder emhlophe ehlangene, ayikho i-metallic luster, indawo eqinile.

Ukulimala: i-pad kulula ukuyikhipha futhi amandla ayancipha.

Isizathu: amandla ensimbi ye-solder makhulu kakhulu, futhi isikhathi sokushisa side kakhulu.

7. Ukushisela okubandayo

Izici zokubukeka: Ingaphezulu liyi-granular, futhi ngezinye izikhathi kungase kube nemifantu.

Ukulimala: Amandla aphansi kanye nokungahambi kahle kahle.

Isizathu: i-solder iyanyakaziswa ngaphambi kokuba iqine.

8. Ukungenwa kahle

Izici zokubukeka: i-interface phakathi kwe-solder ne-weldment inkulu kakhulu futhi ayibushelelezi.

Ukulimala: amandla aphansi, akukho ukufinyelela noma isikhathi sokuvula nokuvala.

Isizathu: i-weldment ayihlanzwa.I-Flux ayanele noma ayikhwalithi ephansi.I-weldment ayishisi ngokugcwele.

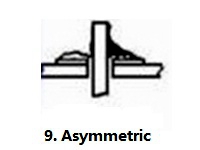

9. Asymmetric

Izici zokubukeka: i-solder ayigelezi phezu kwephedi.

Ukulimala: Amandla anganele.

Isizathu: i-solder ayinamanzi amancane.Ukuguquguquka okunganele noma ikhwalithi ephansi.Ukushisa okunganele.

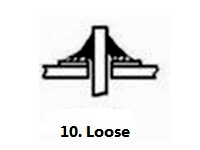

10. Okuxekethile

Izici zokubukeka: Intambo noma ingxenye yomthofu ingasuswa.

Ukulimala: kubi noma okungaqhubeki.

Isizathu: ngaphambi kokuthi i-solder iqine, intambo eholayo iyahamba ukuze ibangele izikhala.Umthofu awucutshungulwanga kahle.

11. I-Cusp

Izici zokubukeka: bukhali.

Ukulimala: ukubukeka kabi, kulula ukubangela ukuvala ibhuloho

Isizathu: ukugeleza okuncane kakhulu nesikhathi sokushisa eside kakhulu.I-angle yokushiya ye-soldering iron ayilungile.

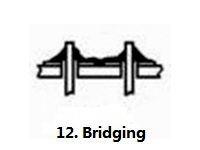

12. Ukuhlanganisa

Izici zokubukeka: izintambo eziseduze zixhunyiwe.

Ukulimala: Isifunda esifushane sikagesi.

Isizathu: solder kakhulu.I-engeli engalungile yokuhoxiswa kwe-solder iron.

13. Iphinifa

Izici zokubukeka: ukuhlola okubonakalayo noma izikhulisamandla ezinamandla aphansi zingabona izimbobo.

Ukulimala: amandla anganele, i-solder joint kulula ukugqwala.

Isizathu: igebe phakathi komthofu nembobo yephedi likhulu kakhulu.

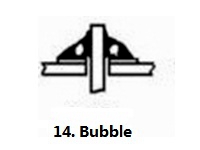

14. Igwebu

Izici zokubukeka: kukhona iqhubu le-solder eliphefumula umlilo empandeni yomthofu, futhi umgodi ufihliwe ngaphakathi.

Ukulimala: ukuqhutshwa kwesikhashana, kodwa kulula ukubangela ukungahambi kahle isikhathi eside.

Isizathu: igebe phakathi kokuhola kanye nomgodi we-welding disc likhulu.Ukungena kahle komthofu.Isikhathi sokushisela sokuxhunywa kwezinhlangothi ezimbili emigodini side, futhi umoya osezimbobeni uyakhula.

15. Ucwecwe lwethusi olusontekile

Izici zokubukeka: i-foil yethusi ihlutshiwe ebhodini eliphrintiwe.

Ingozi: I-PCB yonakele.

Isizathu: isikhathi sokushisela side kakhulu futhi izinga lokushisa liphezulu kakhulu.

16. Khubula

Izici zokubukeka: amalunga e-solder aphuma ku-foil yethusi (hhayi i-copper foil ne-PCB).

Ukulimala: Isekhethi evulekile.

Isizathu: ukufakwa kwensimbi embi kuphedi.

I-PCBFuture ihlinzeka ngazo zonke izinsiza zokuhlanganisa ze-PCB ezibandakanya konke, okuhlanganisa ukukhiqizwa kwe-PCB, ukuthola ingxenye kanye nokuhlanganiswa kwe-PCB.EyethuIsevisi ye-Turnkey PCBiqeda isidingo sakho sokuphatha abahlinzeki abaningi ngezikhathi eziningi, okuholela ekwengezeni ukusebenza kahle kanye nokusebenza kahle kwezindleko.Njengenkampani eqhutshwa ikhwalithi, sisabela ngokugcwele ezidingweni zamakhasimende, futhi singahlinzeka ngezinsizakalo ezifika ngesikhathi kanye nezomuntu siqu izinkampani ezinkulu ezingeke zilingise.Singakusiza ukuthi ugweme ukonakala kwe-PCB ekuthengisweni kwemikhiqizo yakho.

Isikhathi sokuthumela: Nov-06-2021