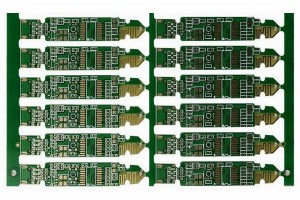

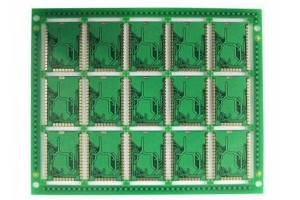

Ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza nokunciphisa izindleko zokukhiqiza kuUkuhlanganiswa kwe-PCBinqubo, amabhodi wesifunda angenalutho ngokuvamile enze iphaneli ukukhiqizwa, okungase kube lula PCBA processing plant ukufeza chip Welding.Okulandelayo kuzokhuluma ngezindlela ezijwayelekile zamaphaneli nezimiso zebhodi lesifunda.

Isimiso sepaneli ye-PCB:

1. Ubukhulu bebhodi lebhodi le-PCB ububanzi ≤ 300mm (umugqa we-Fuji);uma udinga ukusabalalisa okuzenzakalelayo , usayizi we-PCB kufanele ≤ 125mm(W) × 180mm(L).

2. Ukuma kwe-PCB kufanele kube seduze nesikwele ngangokunokwenzeka, futhi kunconywa ibhodi lokuhlanganisa (2*2,3 *3,4*4) kuphaneli ngayinye.

3. Uhlaka lwangaphandle (i-clamping edge) lwebhodi lesekethe luzosebenzisa idizayini eyiluphu evaliwe ukuze kuqinisekiswe ukuthi iphaneli ye-PCB ngeke iguge ngemva kokuba isilungisiwe ku-fixture.

4. Ibanga elincane lesikhungo sebhodi le-PCB lizolawulwa ngo-75mm~145mm.

5. Angeke kube khona amathuluzi amakhulu noma amathuluzi aphumayo eduze nendawo yokuxhuma phakathi kohlaka lwangaphandle lwebhodi lokuhlanganisa nebhodi elincane langaphakathi, futhi kuyoba nesikhala esikhulu kuno-0.5mm phakathi kwezingxenye kanye nomkhawulo webhodi le-PCB ukuze qinisekisa ukusebenza okuvamile kwethuluzi lokusika.

6. Emagumbini amane ohlaka lwangaphandle lwe-PCB, kuvulwa izimbobo ezine zokubeka futhi ububanzi bembobo bungu (4mm ± 0.01mm);Amandla embobo kufanele abe ngokulinganisela ukuqinisekisa ukuthi ngeke aphuke ngesikhathi senqubo yokulayishwa nokukhipha;Ububanzi bembobo kanye nokunemba kwendawo kufanele kube phezulu, futhi imbobo izoba bushelelezi.

7. Ibhodi ngalinye elincane ku-PCB kufanele libe nezimbobo zokubeka okungenani ezintathu, 3 ≤ ububanzi bembobo ≤ 6mm, futhi izintambo noma i-SMT ayivunyelwe phakathi kuka-1mm wembobo yokumisa onqenqemeni.

8. Uma usetha indawo yokuma kwereferensi, indawo yokushisela engamelani engu-1.5mm enkulu kunephuzu lokumisa ivamise ukugcinwa eduze nendawo yokuma.

9. Izingxenye ezinkulu zizohlinzekwa ngezikhala zokumisa noma izimbobo zokubeka, njengalezi: umbhobho, isixhumi esibonakalayo sebhethri, i-microswitch, isixhumi esibonakalayo samahedsethi, injini, njll.

Izindlela ezijwayelekile ze-PCB ezixhumeke kuphaneli:

1, V-CUT

I-V-CUT isho ukuthi amabhodi amaningana noma ibhodi elifanayo lingahlanganiswa futhi lihlanganiswe ndawonye, bese-ke i-V-groove ingasikwa ngomshini we-V-CUT phakathi kwamabhodi ngemva kokucubungula kwe-PCB, engaphulwa ngesikhathi sokusetshenziswa.Kuyindlela ethandwa kakhulu namuhla.

2. Ukubhoboza umsele

Ukushaya kusho ukugaya okungenalutho phakathi kwamapuleti noma amapuleti angaphakathi anomshini wokugaya njengoba kudingekile, okulingana nokumba ngaphandle.

3. Imbobo yesitembu

Lokhu kusho ukuthi sebenzisa imbobo encane ukuxhumanisa ibhodi le-PCB, elibukeka njengomumo we-sawtooth esitembuni, ngakho-ke libizwa ngokuthi isixhumanisi sembobo yesitembu.Isixhumanisi sembobo yesitembu sidinga i-burr yokulawula okuphezulu ezungeze ibhodi, okuwumgodi omncane wesitembu ongasetshenziswa ukufaka esikhundleni somugqa we-V.

Ufuna ukwazi okwengeziwe, sicela uchofoze: www.PCBfuture.com

Isikhathi sokuthumela: Jan-13-2022