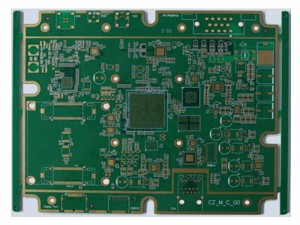

A Ukuhlanganiswa kwe-PCBtest stand iyidivayisi esetshenziswa ukuhlola PCB imikhiqizo ekupheleni komhlangano.Lapho wenza ama-racks okuhlola umhlangano we-PCB, izitshalo zokucubungula umhlangano we-PCB ngokuvamile zidinga ukuhlinzeka ngamafayela e-Gerber namasampula omhlangano we-PCB ukuze kube lula ukukhiqizwa kwama-rack okuhlola.Ebhentshini lamanje lokuhlola umhlangano we-PCB, amabhakede ambalwa kuphela wepuleti lokucindezela afakwe endaweni yokuhlola, futhi umhlangano we-PCB ulungiswa nge-thimble kanye nebhande lepuleti lokucindezela.Ngesikhathi sokuhlolwa kokusebenza kokuhlanganiswa kwe-PCB, cindezela ukuhlanganisa kwe-PCB ku-clamp ngezandla zombili.Ngenxa yokuhlanganiswa kwe-PCB ngamandla angalingani noma ukucindezela okunganele, kulula ukwenza iphinikhodi yokuhlola futhi umhlangano we-PCB ube nokuxhumana okungalungile, okuthinta kakhulu ukusebenza kahle kokuhlolwa nokunemba.Uma amandla amakhulu kakhulu, kulula ukuwohloka noma ukulimaza lapho umhlangano we-PCB ucindezelwa phansi, futhi kulula ukulimaza iphinikhodi yokuhlola yesitendi sokuhlola.dala ukulahlekelwa okukhulu.

1. Ukulungiselela izinto ezibonakalayo.

Ngemuva kokunquma uhlelo ngokuya ngedatha, kuyadingeka ukulungisa izinto ze-Hardware (izingxenye ze-elekthronikhi), amasekhethi ahlobene ahlobene, okokusebenza, izinto zohlaka (njengebhodi le-acrylic), iglue, inqwaba kagesi, izikulufo, izinto zocingo, njll., ukunquma idatha yohlelo lokukhiqiza.

2. Ukunqunywa nokuhlolwa kwesakhiwo sesitendi sokuhlola

3. Izidingo zocingo

(1) Intambo yokuvula idinga ukuvulwa phakathi kuka-2mm.Okokuqala engeza ithini endaweni yokuvula ucingo kanye nendawo yocingo lwethayela enaliti yokuhlola.

(2) Intambo eshiselwe akufanele ibe nokushwiba noma ukuxega.

(3) Hlukanisa izintambo eziqinile nezibuthakathaka endaweni yokuhlola bese ubopha izintambo ngezintambo.

(4) Amalunga e-ammeter kanye ne-voltmeter kufanele afakwe ngepeni le-multimeter.Amapulagi kabhanana awakwazi ukufakwa ukuze kuhlolwe ukusebenza kwamanje, i-voltage neminye ukuze kuqinisekiswe ukuphepha komqhubi.

(5) Ulayini wesignali wokuxhunywa kwemodeli yomkhiqizo wemvamisa ephezulu kufanele usebenzise ucingo oluvikelekile ukuze kuqinisekiswe ukuphepha kokuphansi kwenethiwekhi yangaphandle.

(6) Uma kunomlilo ohlakeni lokukala, imbobo yomlilo kumele iqiniswe.

(7) Izitendi zokuhlola kufanele zifakwe i-fuse, futhi azikwazi ukushintshwa izintambo noma ezinye izintambo zokuphothula.Susa i-13A fuse kupulaki yasekuqaleni.Lapho ushintsha i-fuse, naka ukuthi imodeli engaphansi kwezidingo zokuhlolwa ingakanani okwamanje.Isimiso sokushintshwa sinqunywa ukusebenza kwamanje komkhiqizo izikhathi ezingu-8 -10 zanele.

4. Ukukhethwa kwamaphuzu okuhlolwa kwekhwalithi kumele kulandele imigomo yokuqondanisa, ukusebenza ngempumelelo kanye nomnotho.

I-PCBFuture izakhele igama elihle embonini yenkonzo yomhlangano ye-turnkey PCBumhlangano we-PCB oyisibonelokanye nevolumu ephansi, umhlangano we-PCB wevolumu ephakathi.Okudingeka amakhasimende ethu akwenze ukusithumelela amafayela edizayini ye-PCB nezimfuneko, futhi singawunakekela wonke umsebenzi.Sikwazi ngokugcwele ukuhlinzeka ngezinsizakalo ze-PCB ze-turnkey ezingenakunqotshwa kodwa sigcine izindleko ziphelele ngaphakathi kwesabelomali sakho.

Uma ufuna umenzi womhlangano we-Turnkey PCB okahle, sicela uthumele amafayela akho e-BOM namafayela e-PCB kusales@pcbfuture.com.Wonke amafayela akho ayimfihlo kakhulu.Sizokuthumelela isilinganiso esinembile nesikhathi sokuhola emahoreni angama-48.

Isikhathi sokuthumela: Aug-23-2022