1. Ukufakwa Kweminwe

In Ukuhlolwa kwe-PCB, izinsimbi ezingavamile zinamathiselwe esixhunyweni sonqenqema lwebhodi, unqenqema lwebhodi ukuthintana okuvelele noma umunwe wegolide ukuze unikeze ukumelana okuphansi kokuxhumana nokumelana nokugqoka okuphezulu, okubizwa ngokuthi i-finger plating noma i-plating yendawo ephumayo.Inqubo imi kanje:

1) cwecwa i-coating bese ukhipha ithayela noma i-tin lead coat endaweni ethintwayo.

2) ukugeza ngamanzi.

3) khuhla nge-abrasive.

4) ukusebenza kuhlakazeke ku-10% sulfuric acid.

5) ukujiya kwe-nickel plating ekuthinteni okuphumela ngaphandle kungu-4-5 μ m.

6) Hlanza ukususa amanzi amaminerali.

7) ukulahlwa kwesixazululo sokucwiliswa kwegolide.

8) igolide Plating.

9) ukuhlanza.

10) ukomisa.

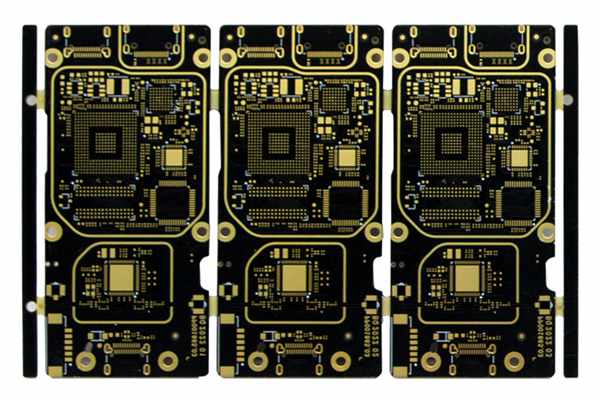

2. Nge-plating

Kunezindlela eziningi zokusetha isendlalelo se-electroplating esifanelekayo odongeni lwembobo yokumba i-substrate, okubizwa ngokuthi i-hole wall activation kuzinhlelo zokusebenza zezimboni.Inqubo yokusetshenziswa kwezentengiselwano yesifunda sayo esiphrintiwe idinga amathangi amaningi okugcina aphakathi nendawo, ngalinye elinezidingo zalo zokulawula nokugcinwa kwazo.I-Via electroplating iyinqubo yokukhiqiza edingekayo yenqubo yokukhiqiza yokumba.Lapho i-drill bit ibhoboza i-foil yethusi kanye ne-substrate yayo engaphansi, ukushisa okukhiqizwayo kufinyela inhlaka yokwenziwa evikelayo eyakha ingxenye enkulu ye-substrate, futhi inhlaka ejiyile kanye nezinye izinsalela zokumba zinqwabelana eduze kwembobo futhi zimbozwe odongeni lwembobo esanda kuvezwa. ku-foil yethusi, kanye ne-resin ehlanganisiwe izophinde ishiye ungqimba lwe-axis eshisayo odongeni lomgodi we-substrate;Ibonisa ukunamatheliswa okungalungile kuzicishazi eziningi, okudinga ukuthuthukiswa kohlobo lobuchwepheshe olufana nesenzo samakhemikhali sokususwa kwamabala kanye nokugqwala emuva.

Indlela efaneleke kakhulu yokuqinisekisa i-PCB ukusebenzisa uyinki we-viscosity ophansi oklanywe ngokukhethekile, onokunamathela okuqinile futhi ongaboshelwa kalula ezindongeni eziningi ezishisayo ezipholishiwe, ngaleyo ndlela kuqedwe isinyathelo se-tchback.

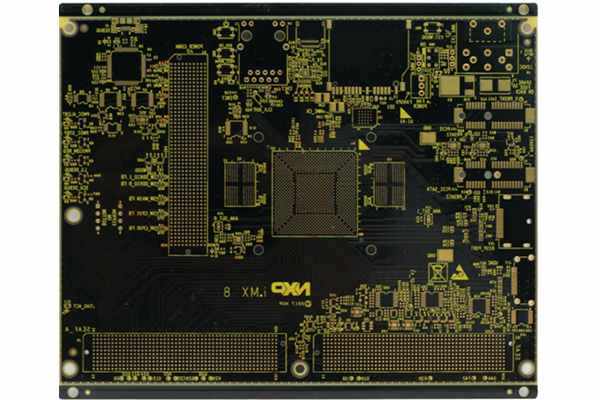

3.I-roller exhunywe i-plating ekhethiwe

Izikhonkwane nezikhonkwane zokuxhumana zezingxenye ze-elekthronikhi, njengezixhumi, ama-circuits ahlanganisiwe, ama-transistors kanye namasekethe aphrintiwe aguquguqukayo, akhethiwe ngokukhetha ukuze kuzuzwe ukumelana okuhle kokuxhumana nokumelana nokugqwala.Le ndlela ye-electroplating ingaba ngesandla noma ngokuzenzakalelayo.Kubiza kakhulu ukumisa ukukhetha kwephinikhodi ngayinye, ngakho-ke i-batch welding kufanele isetshenziswe.Ekukhetheni indlela yokucwenga, qala ngokugcoba ungqimba lwefilimu ye-inhibitor ezingxenyeni zefoyili yethusi yensimbi engadingi i-electroplating, futhi umise kuphela ukufakwa kwe-electroplating kucwecwe lethusi elikhethiwe.

4.Ibhulashi lokucwenga

I-brush plating ubuchwepheshe be-electrostacking, obumisa kuphela i-electroplating endaweni elinganiselwe futhi abunawo umthelela kwezinye izingxenye.Imvamisa, izinsimbi ezingavamile zigqitshwa ezingxenyeni ezikhethiwe zebhodi lesifunda eliphrintiwe, njengezindawo ezifana nezixhumi zonqenqema lwebhodi.I-brush plating isetshenziswa kabanzi kuama-workshops e-electronic assemblyukulungisa amabhodi esekethe kadoti.

I-PCBFuture izakhele igama elihle embonini yenkonzo yomhlangano ye-turnkey PCB yomhlangano we-PCB oyisibonelo kanye nevolumu ephansi, umhlangano we-PCB wevolumu ephakathi.Okudingeka amakhasimende ethu akwenze ukusithumelela amafayela edizayini ye-PCB nezimfuneko, futhi singawunakekela wonke umsebenzi.Sikwazi ngokugcwele ukuhlinzeka ngezinsizakalo ze-PCB ze-turnkey ezingenakunqotshwa kodwa sigcine izindleko ziphelele ngaphakathi kwesabelomali sakho.

Uma ufuna umenzi womhlangano we-Turnkey PCB okahle, sicela uthumele amafayela akho e-BOM namafayela e-PCB ku sales@pcbfuture.com.Wonke amafayela akho ayimfihlo kakhulu.Sizokuthumelela isilinganiso esinembile nesikhathi sokuhola emahoreni angama-48.

Isikhathi sokuthumela: Dec-13-2022