Ekuqinisekiseni i-PCB, ungqimba lwe-lead-tin resist lugqitshwa ngaphambili engxenyeni ye-foil yethusi okufanele igcinwe oqweqweni olungaphandle lwebhodi, okungukuthi, ingxenye eyisithombe yesekethe, bese kuthi ucwecwe lwethusi olusele luqoshwe ngamakhemikhali. kude, okubizwa ngokuthi i-etching.

Ngakho, kuUkuhlolwa kwe-PCB, yiziphi izinkinga okufanele zinakwe ekudwebeni?

Imfuneko yekhwalithi yokushumeka iwukuba ukwazi ukususa ngokuphelele zonke izingqimba zethusi ngaphandle kwangaphansi kwesendlalelo esilwa nokuqothuka.Ukukhuluma ngokuqinile, ikhwalithi yokunamathisela kufanele ifake ukufana kobubanzi bentambo kanye nezinga lokunamathisela ohlangothini.

Inkinga ye-side etching ivame ukuphakanyiswa futhi kuxoxwe ngayo ekudwebeni.Isilinganiso sobubanzi be-etch eseceleni kuya ekujuleni kwe-etch ibizwa ngokuthi i-etch factor.Embonini yesekethe ephrintiwe, idigri encane ye-etch eseceleni noma into ephansi ye-etch factor eyanelisa kakhulu.Isakhiwo semishini yokuqopha kanye nezingoma ezihlukene zesixazululo sokunamathisela kuzothinta isici se-etching noma i-side etching degree.

Ngezindlela eziningi, ikhwalithi ye-etching ikhona isikhathi eside ngaphambi kokuba ibhodi lesifunda lingene emshinini wokukhipha.Ngenxa yokuthi kukhona ukuxhumana okuseduze kakhulu kwangaphakathi phakathi kwezinqubo ezihlukahlukene zokuqinisekisa kwe-PCB, ayikho inqubo engathinteki kwezinye izinqubo futhi engathinti ezinye izinqubo.Izinkinga eziningi ezihlonzwe njengekhwalithi ye-etch zazikhona ngempela ohlelweni lokukhumula ngisho nangaphambilini.

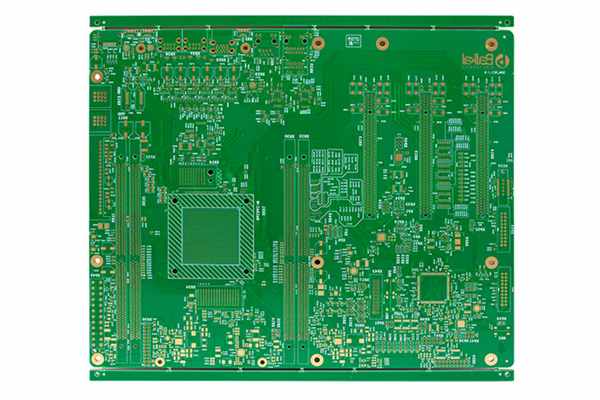

Uma sikhuluma ngokwethiyori, ukuqinisekiswa kwe-PCB kungena esigabeni sokuqopha.Endleleni ye-electroplating yephethini, isimo esifanelekile kufanele sibe: isamba sogqinsi lwethusi nethini lomthofu ngemva kwe-electroplating akumele idlule ukujiya kwefilimu ye-electroplating photosensitive film, ukuze iphethini ye-electroplating imbozwe ngokuphelele nhlangothi zombili zefilimu."Udonga" luyavimba futhi lufakwe kulo.Kodwa-ke, ekukhiqizeni kwangempela, iphethini yokumboza inkulu kakhulu kunephethini ye-photosensitive;njengoba ukuphakama kwe-coating kudlula ifilimu e-photosensitive, kukhona ukuthambekela kokuqoqwa kwe-lateral, futhi ungqimba lwe-tin noma i-lead-tin ukumelana olumbozwe ngaphezu kwemigqa ludlulela ezinhlangothini zombili, lwenza "i-Edge", ingxenye encane yefilimu e-photosensitive. imbozwe ngaphansi “konqenqema”."Umphetho" owenziwe nge-tin noma i-lead-tin yenza kube nzima ukususa ngokuphelele ifilimu e-photosensitive lapho ususa ifilimu, ushiya ingxenye encane "yeglue esele" ngaphansi "konqenqemeni", okuholela ekufakweni okungaphelele.Imigqa yakha “izimpande zethusi” nhlangothi zombili ngemva kokusika, okunciphisa isikhala somugqa, okubangelaibhodi ephrintiweukwehluleka ukuhlangabezana nezidingo zekhasimende futhi ingase yenqatshwe.Izindleko zokukhiqiza ze-PCB zenyuka kakhulu ngenxa yokwenqatshwa.

Ekuhlolweni kwe-PCB, uma sekunenkinga ngenqubo yokufaka, kufanele kube inkinga yenqwaba, ezogcina idale izingozi ezinkulu ezifihliwe kwikhwalithi yomkhiqizo.Ngakho-ke, kubaluleke kakhulu ukuthola ofanelekayoUmkhiqizi wokuqinisekisa we-PCB.

I-PCBFuture izakhele igama elihle embonini yenkonzo yomhlangano ye-turnkey PCB yomhlangano we-PCB oyisibonelo kanye nevolumu ephansi, umhlangano we-PCB wevolumu ephakathi.Okudingeka amakhasimende ethu akwenze ukusithumelela amafayela edizayini ye-PCB nezimfuneko, futhi singawunakekela wonke umsebenzi.Sikwazi ngokugcwele ukuhlinzeka ngezinsizakalo ze-PCB ze-turnkey ezingenakunqotshwa kodwa sigcine izindleko ziphelele ngaphakathi kwesabelomali sakho.

Uma ufuna umenzi womhlangano we-Turnkey PCB okahle, sicela uthumele amafayela akho e-BOM namafayela e-PCB kusales@pcbfuture.com. Wonke amafayela akho ayimfihlo kakhulu.Sizokuthumelela isilinganiso esinembile nesikhathi sokuhola emahoreni angama-48.

Isikhathi sokuthumela: Dec-09-2022