Kungani kufanele sixhume i-vias ku-PCB?

Ukuze kuhlangatshezwane nezidingo zamakhasimende, i- via hole ebhodini lesekethe kufanele ixhunywe.Ngemuva kokuzijwayeza okuningi, inqubo yembobo yepulaki ye-aluminium yendabuko iyashintshwa, futhi inetha elimhlophe lisetshenziselwa ukuqedela i-welding yokumelana ne-plug yebhodi lebhodi lesifunda, elingenza ukukhiqizwa kuzinze kanye nekhwalithi enokwethenjelwa.

I-Via hole idlala indima ebalulekile ekuxhumaneni kwamasekhethi.Ngokuthuthukiswa kwemboni ye-elekthronikhi, iphinde ikhuthaze ukuthuthukiswa kwe-PCB, futhi ibeka phambili izidingo eziphakeme zeUkwakhiwa nokuhlanganiswa kwe-PCBubuchwepheshe.I-Via hole plug technology yaba khona, futhi lezi zidingo ezilandelayo kufanele zihlangatshezwe:

(1) Ikhopha embobeni ye-via yanele, futhi imaski ye-solder ingaxhunywa noma cha;

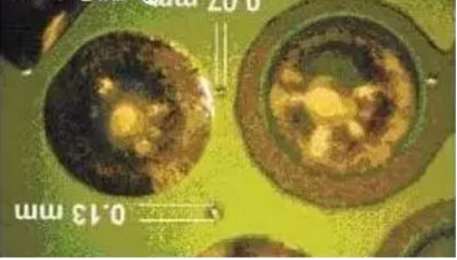

(2) Kumelwe kube nethayela nomthofu embotsheni ye-via, enesidingo esithile sokujiya (ama-microns ama-4), kungabikho uyinki ovimbela i-solder embobeni, obangela ukuthi ubuhlalu bethayela bufihlwe emigodini;

(3) Kumelwe kube nembobo yepulaki kayinki ekwazi ukumelana ne-solder embotsheni ye-via, engabonakali, futhi akumele kube nendandatho kathayela, ubuhlalu bethayela kanye nesicaba.

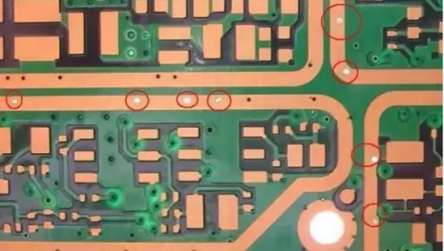

Ngokuthuthukiswa kwemikhiqizo ye-elekthronikhi ekuqondeni "kokukhanya, okuncane, okufushane nokuncane", i-PCB nayo ithuthukela ekuminyana okuphezulu kanye nobunzima obukhulu.Ngakho-ke, inani elikhulu lama-PCB e-SMT kanye ne-BGA avele, futhi amakhasimende adinga izimbobo zokuxhuma lapho efaka izingxenye, ikakhulukazi ezinemisebenzi emihlanu:

Ngokuthuthukiswa kwemikhiqizo ye-elekthronikhi ekuqondeni "kokukhanya, okuncane, okufushane nokuncane", i-PCB nayo ithuthukela ekuminyana okuphezulu kanye nobunzima obukhulu.Ngakho-ke, inani elikhulu lama-PCB e-SMT kanye ne-BGA avele, futhi amakhasimende adinga izimbobo zokuxhuma lapho efaka izingxenye, ikakhulukazi ezinemisebenzi emihlanu:

(1) Ukuze ugweme ukujikeleza okufushane okubangelwa uthayela olungena endaweni ngesikhathi se-PCB phezu kwe-wave soldering, ikakhulukazi uma sibeka imbobo ku-BGA pad, kufanele siqale senze imbobo yepulaki bese sifaka igolide ukuze sikwazi ukuhlanganisa i-BGA. .

(2) Gwema izinsalela ezigelezayo emigodini;

(3) Ngemva kokukhweza okungaphezulu kanye nokuhlanganiswa kwengxenye yefekthri kagesi, i-PCB kufanele imunce i-vacuum ukuze yenze ingcindezi engalungile emshinini wokuhlola;

(4) Vimbela i-solder engaphezulu ukuthi ingagelezi embobeni, futhi ibangele ukusoda okungelona iqiniso futhi ithinte intaba;

(5) vimbela ubuhlalu be-solder ekuphumeni ngesikhathi sokushiswa kwamagagasi, futhi kubangele ukujikeleza okufushane.

Ukugcwaliseka kobuchwepheshe be-plug hole ngembobo

NgobaUmhlangano we-SMT PCBibhodi, ikakhulukazi ukukhwezwa kwe-BGA ne-IC, ipulaki ye-via hole kufanele ibe isicaba, i-convex ne-concave plus noma khipha 1mil, futhi akumele kube khona ithini elibomvu onqenqemeni lwembobo ye-via;ukuze kuhlangatshezwane nezidingo zekhasimende, inqubo yembobo ye-hole plug ingachazwa njenge-multifarious, ukugeleza kwenqubo ende, ukulawulwa kwenqubo enzima, kuvame ukuba nezinkinga ezifana nokwehla kwamafutha ngesikhathi sokulinganisa komoya oshisayo kanye nokuhlolwa kokumelana ne-solder kawoyela oluhlaza kanye nokuqhuma kukawoyela ngemuva. ukwelapha.Ngokwezimo zangempela zokukhiqiza, sifingqa izinqubo ezihlukahlukene zembobo yepulaki ye-PCB, futhi senza ukuqhathanisa nokuchaza kabanzi ngenqubo kanye nezinzuzo kanye nokubi:

Qaphela: isimiso sokusebenza sokulinganisa komoya oshisayo ukusebenzisa umoya oshisayo ukususa i-solder eyeqile phezu kwebhodi lesifunda eliphrintiwe kanye nasemgodini, kanti i-solder esele imbozwe ngokulinganayo phezu kwephedi, imigqa engavimbeli ye-solder kanye nezindawo zokupakisha zangaphezulu. , okungenye yezindlela zokwelashwa okungaphezulu kwebhodi lesifunda eliphrintiwe.

1. Inqubo yokuxhuma imbobo ngemva kokulinganisa komoya oshisayo: ukushisela ukumelana nepuleti → HAL → imbobo yepulaki →ukwelapha.Inqubo yokungaxhumi yamukelwa ukukhiqizwa.Ngemva kokulinganisa komoya oshisayo, isikrini se-aluminium noma isikrini sokuvimbela inki sisetshenziselwa ukuqedela ipulaki yembobo yazo zonke izinqaba ezidingwa amakhasimende.Uyinki wembobo yokuxhuma ungaba uyinki ozwelayo noma uyinki we-thermosetting, esimweni sokuqinisekisa umbala ofanayo wefilimu emanzi, uyinki wembobo yepulaki kungcono kakhulu ukusebenzisa uyinki ofanayo nebhodi.Le nqubo ingaqinisekisa ukuthi imbobo edlulayo ngeke iwise uwoyela ngemva kokulinganisa komoya oshisayo, kodwa kulula ukubangela ukuthi uyinki wembobo yepulaki ingcolise indawo yepuleti futhi ingalingani.Kulula kumakhasimende ukuthi abangele i-soldering engamanga ngesikhathi sokukhweza (ikakhulukazi i-BGA).Ngakho, amakhasimende amaningi awayamukeli le ndlela.

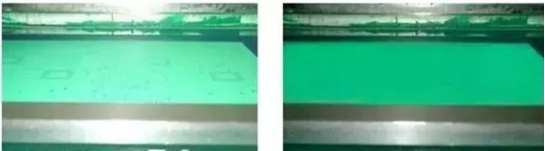

2. Inqubo yokuxhuma imbobo ngaphambi kokulinganisa komoya oshisayo: 2.1 xhuma imbobo eneshidi le-aluminium, qinisa, gaya ipuleti, bese udlulisela izithombe.Le nqubo isebenzisa umshini wokumba we-CNC ukubhoboza ishidi le-aluminium elidinga ukuxhunywa imbobo, ukwenza ipuleti lesikrini, imbobo yokuxhuma, iqinisekise imbobo yepulaki yembobo egcwele, uyinki wembobo yepulaki, uyinki we-thermosetting nawo ungasetshenziswa.Izici zayo kufanele kube ubulukhuni obukhulu, ushintsho oluncane lokushwabana kwe-resin, nokunamathela okuhle ngodonga lwembobo.Inqubo yobuchwepheshe imi kanje: ukwelapha kusengaphambili → imbobo yepulaki → ipuleti lokugaya → ukudluliswa kwephethini → ukunamathisela → ukushisela ukumelana nepuleti.Le ndlela ingaqinisekisa ukuthi imbobo yepulaki yembobo ibushelelezi, futhi ukulinganisa komoya oshisayo ngeke kube nezinkinga zekhwalithi njengokuqhuma kukawoyela nokuwa kukawoyela onqenqemeni lwembobo.Kodwa-ke, le nqubo idinga ukujiya kwethusi okwesikhathi esisodwa ukuze ugqinsi lwethusi lodonga lwembobo luhlangabezane nezinga lekhasimende.Ngakho-ke, inezidingo eziphakeme ze-copper plating yepuleti yonke kanye nokusebenza kwe-plate grinder, ukuze kuqinisekiswe ukuthi i-resin ebusweni bethusi isuswe ngokuphelele, futhi indawo yethusi ihlanzekile futhi ayingcolisiwe.Amafekthri amaningi e-PCB awanayo inqubo yethusi ejiya ngesikhathi esisodwa, futhi ukusebenza kwemishini akukwazi ukuhlangabezana nezidingo, ngakho le nqubo ayivamile ukusetshenziswa ezimbonini ze-PCB.

(Isikrini sikasilika esingenalutho) (Inethi yefilimu yendawo yokudayisa)

We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets. For more information, please email to service@pcbfuture.com.

Isikhathi sokuthumela: Jul-01-2021